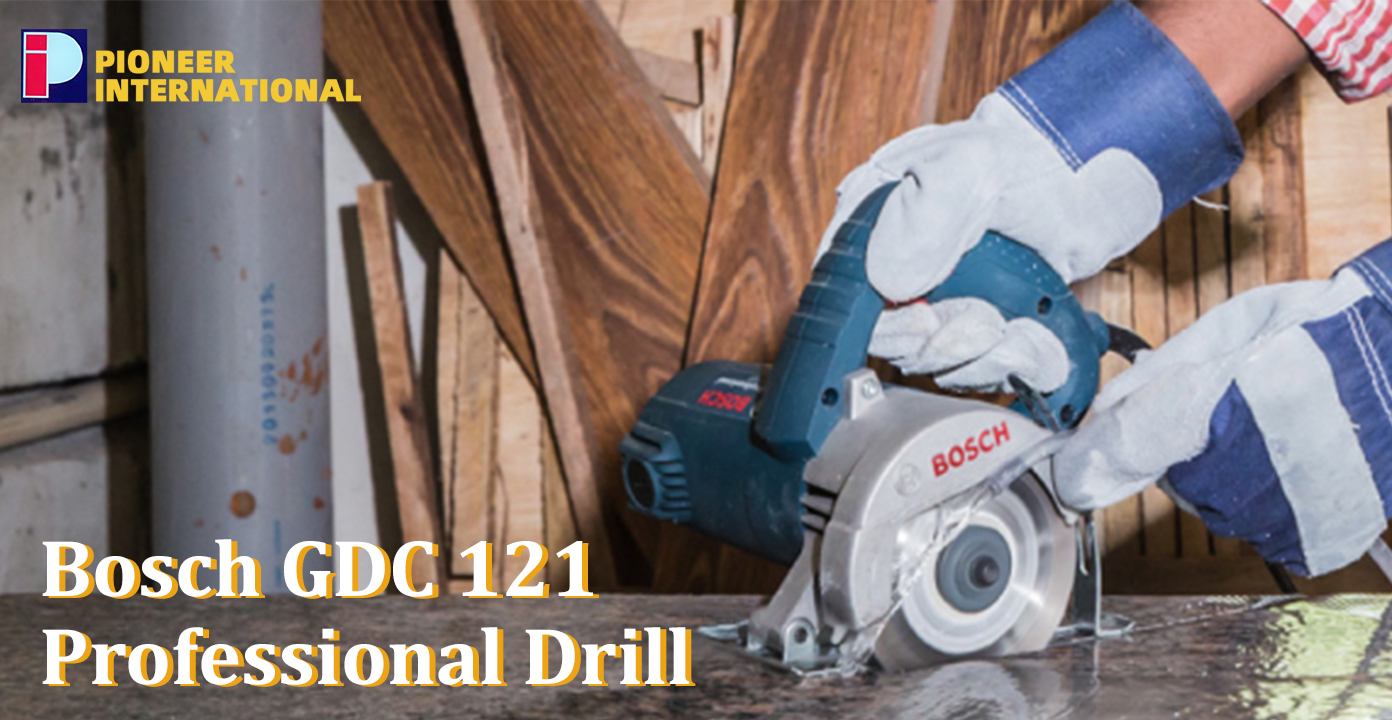

Industrial Applications and Performance Metrics of Bosch GDC 121 Professional Drill

The Bosch GDC 121 Professional Drill is engineered for precision drilling and heavy-duty industrial applications. Its robust design ensures consistent performance, operational reliability, and long-term durability, making it suitable for a wide range of metal, wood, and composite materials.

Poineer International, a trusted exporter and importer of Bosch professional tools, guarantees global access to authentic GDC 121 drills, ensuring industrial buyers receive high-quality equipment with complete technical support and certification compliance.

- Industrial-Grade Motor: High-efficiency 1,100 W motor designed for continuous operation in industrial environments.

- Variable Speed Control: 500–3,200 RPM for precise material-specific drilling.

- Ergonomic Construction: Designed for reduced operator fatigue during extended use.

- Heavy-Duty Chuck: 13 mm keyless chuck for easy bit changes and secure grip.

- Precision Drilling: High torque output for consistent hole quality in various materials.

- Integrated Safety Mechanisms: Thermal overload protection and auto-stop functions.

- Compact and Balanced Design: Facilitates ease of handling in confined workshop spaces.

- Durable Components: Hardened steel gears and reinforced housing.

- Dust Protection: Shielding for motor and components against metal and wood dust.

- Export-Ready Certification: CE and ISO certified for global industrial markets.

Specifications & Performance Metrics

| Specification |

Details |

| Model |

GDC 121 Professional Drill |

| Motor Power |

1,100 W |

| No-Load Speed |

500–3,200 RPM |

| Chuck Capacity |

13 mm Keyless |

| Torque |

45 Nm |

| Weight |

3.5 kg |

| Vibration Level |

≤ 2.3 m/s² |

| Noise Level |

82 dB |

| Power Supply |

230 V, 50 Hz |

| Duty Cycle |

Continuous industrial operation |

| Housing Material |

Die-cast aluminum + reinforced polymer |

| Safety Features |

Thermal protection, auto-stop |

| Dust Protection |

Yes, motor shielded |

| Dimensions |

400 x 160 x 140 mm |

| Application Materials |

Metal, wood, composite sheets |

| Drilling Accuracy |

±0.1 mm |

| Manufacturer |

Bosch |

| Supplier |

Poineer International |

| Country of Origin |

Germany |

Industrial Applications & Use Cases

The Bosch GDC 121 Professional Drill is designed for precision and reliability in industrial settings:

- Metal Fabrication Workshops: Precision drilling of stainless steel, aluminum, and mild steel components.

- Construction and Civil Engineering: Suitable for drilling in structural steel, wooden panels, and composite surfaces.

- Automobile Manufacturing: Accurate drilling of chassis components, engine parts, and mounting brackets.

- Furniture and Woodworking: Efficient and precise drilling in solid wood and laminated panels.

- Electronics and Assembly Units: Ideal for creating precise holes in casings and panels.

- Export-Ready Operations: Suitable for industries requiring certified and standardized drilling equipment.

The adjustable speed and robust motor allow operators to adapt the drill for specific material properties, ensuring consistent hole quality and reduced wear on both the tool and workpiece.

Maintenance & Safety Guidelines

Proper maintenance ensures prolonged life, reliability, and operational safety:

- Motor and Gear Inspection: Regularly clean dust shields, inspect gears for wear, and maintain lubrication.

- Bit Replacement: Use only Bosch-approved drill bits; check for wear or defects before use.

- Electrical Safety: Ensure proper grounding and use industrial-grade extension cords.

- Thermal Protection: Monitor motor temperature during extended continuous use; allow cooling periods.

- Operator Safety: Always wear gloves, safety glasses, and hearing protection; avoid loose clothing near the drill.

- Storage: Store in a dry, clean, dust-free environment; use protective covers when not in use.

- Calibration: Periodically check chuck alignment for precision drilling applications.

Advantages & Benefits for Industrial Users

- Precision Drilling: High torque and variable speed settings ensure exact hole dimensions.

- Durability: Built for continuous, heavy-duty industrial operations.

- Operator Comfort: Ergonomic handle design minimizes fatigue.

- Versatility: Suitable for multiple materials including metals, wood, and composites.

- Safety Features: Integrated thermal protection and auto-stop reduce risk of accidents.

- Export-Ready Compliance: CE and ISO certifications make it suitable for international markets.

- Reliability: Designed to withstand harsh industrial environments while maintaining performance.

About Poineer International

Poineer International is a leading exporter and importer of Bosch professional tools, including the GDC 121 Professional Drill. The company has earned a reputation for delivering high-quality, authentic industrial tools worldwide.

Core Competencies:

- Global Export Services: Complete documentation, shipping support, and compliance certifications.

- Technical Expertise: Skilled professionals providing pre-sale consultation and post-sale technical support.

- Authentic Products: Authorized Bosch partner delivering genuine, high-performance tools.

- Bulk Supply & Custom Orders: Tailored solutions for wholesalers, distributors, and industrial clients.

- Industrial Focus: Specialized in high-performance equipment for professional and industrial applications.

By choosing Poineer International, industrial buyers get reliable supply, technical support, and assurance of Bosch quality for their operations.

FAQ Section

Q1: What is the power rating of the Bosch GDC 121?

The drill is equipped with a 1,100 W motor, suitable for heavy-duty industrial use.

Q2: Can it drill metal and wood?

Yes, it is designed for metal, wood, and composite materials with high precision.

Q3: What safety features are included?

Thermal protection, auto-stop, and dust-shielded motor ensure operator safety.

Q4: Does Poineer International provide export services?

Yes, we are a trusted exporter and importer, offering complete documentation and shipping support.

Q5: What is the chuck capacity?

The GDC 121 has a 13 mm keyless chuck for easy and secure bit installation.

Q6: How should it be maintained?

Regular cleaning, inspection of bits, lubrication, and following Bosch maintenance guidelines are essential.